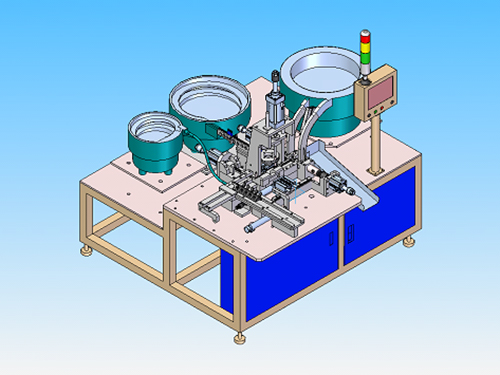

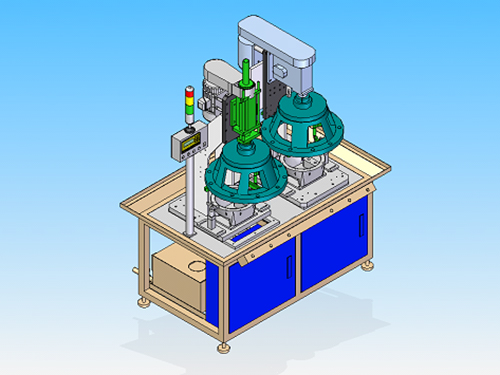

Rotating table Machine

Rotating table Machine:

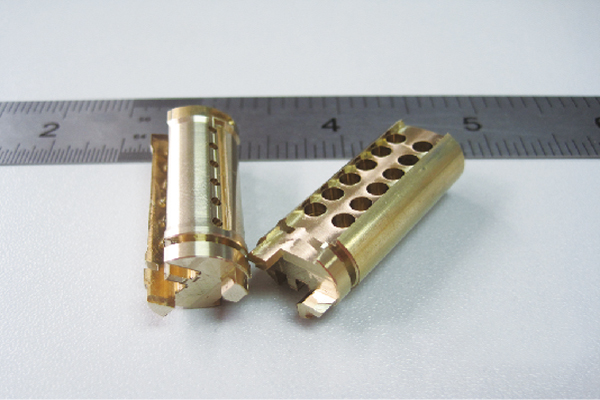

enables one operator to operate multiple devices, greatly reducing labor costs. High-quality, high-precision, high-speed processing of various double-pass, three-way air pressure, hydraulic joints, copper valves and mechanical related parts. Turning, milling, drilling, lining, tapping, forming, grooving, inner and outer diameter grooves and other machining. Multi-direction simultaneous processing, the product is completed at one time, no need to process the workpiece again. Processing materials: iron, copper, aluminum, stainless steel, etc. can choose to use a fully automatic material system. High affinity loop control operation interface, beginners can easily get started. Each workstation can be equipped with various processing functions, such as turning, drilling, tapping, lining, milling grooves, side machining, and inner and outer diameter grooves for project design.

turntable processing machine is currently an efficient processing machine. In the processing and manufacturing of small parts, the time required for each workpiece is about 2 to 6 seconds. In mass production of the same size, this machine can work 24 hours a day. At present, there is no other machine of its kind in the world to compete.

|

|

|

|

|

|

|

|

|

|