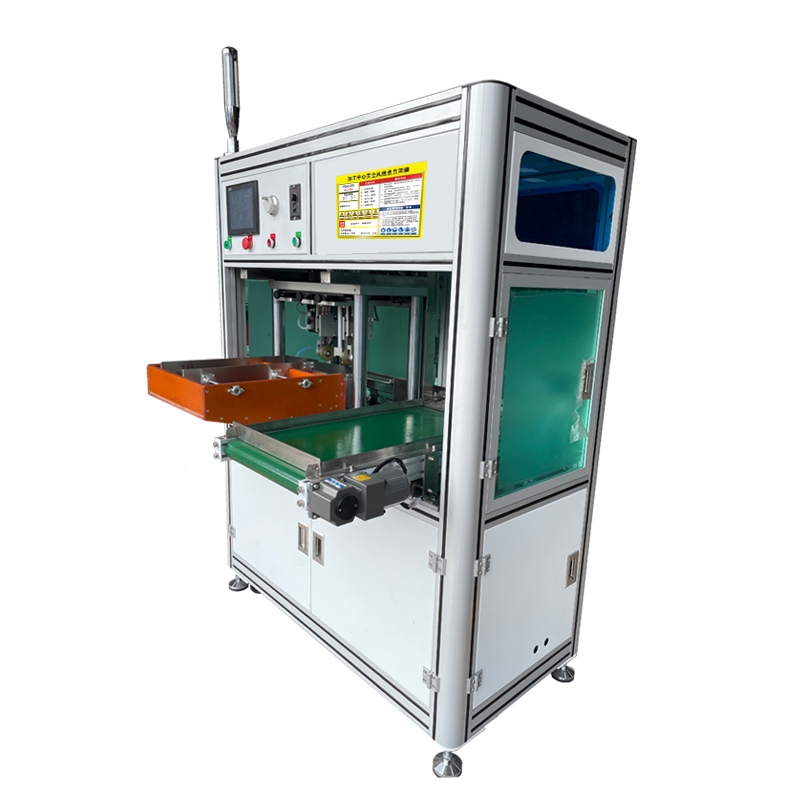

Automatic detection and straightening machine for single position shaft

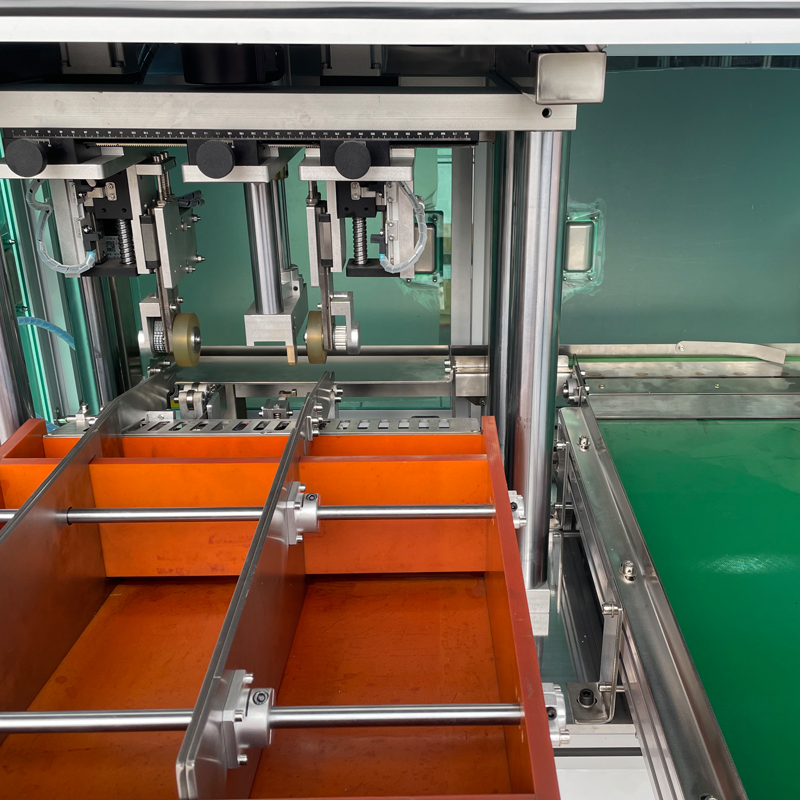

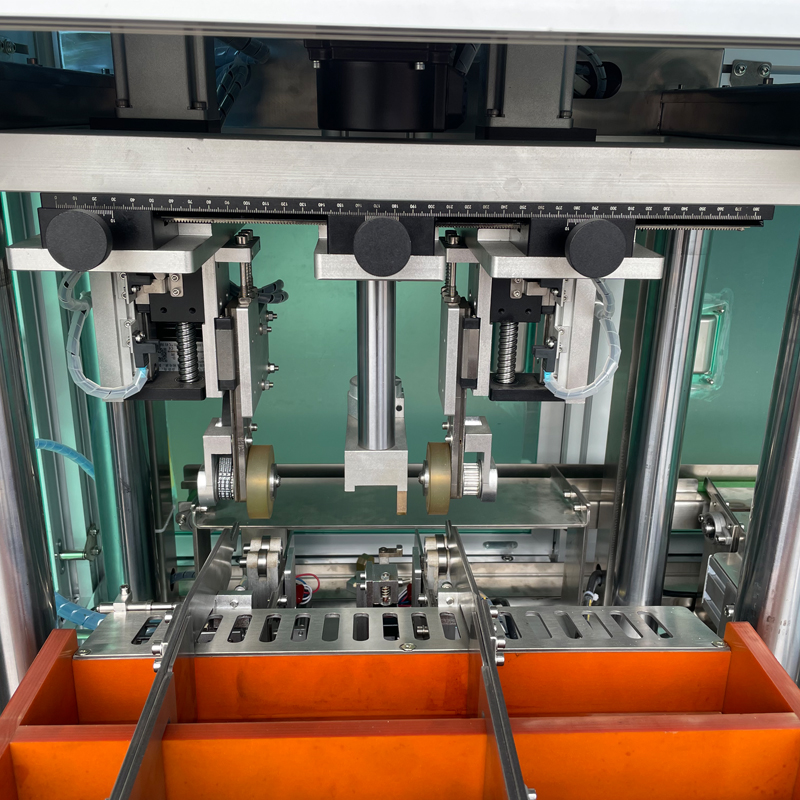

The TB6-12x300 single-station intelligent dynamic straightening machine is built of aluminum profiles. It uses Panasonic laser to detect and transmit data to the servo to collect data automatically to complete straightening. It is mainly used to detect and straighten the outer diameter and size of shaft products. When changing products, it has [one-key learning method] to eliminate the manual and complex tool setting steps. In addition, the equipment is equipped with automatic loading and unloading mechanism, which can realize automatic feeding and receiving functions, reduce labor intensity of employees and improve processing efficiency.

|

No |

Basic items | parameter |

|

1 |

Servo tonnage |

1T |

|

2 |

Straighten the beat about |

1pcs/2-4S |

|

4 |

Straighten product length range |

100-300mm |

|

5 |

Straighten the outer diameter range of the product |

6-12mm |

|

6 |

Straightening tolerance range |

±0.01nm |

|

9 |

Quantity of parts and components that can be placed in the silo |

300-500pcs |

|

10 |

Loading method |

3step feeder |

|

11 |

Material return method |

Conveyor belt |

|

16 |

Control system (PLC or other methods) | Mounter system |

|

7 |

Frame aluminum profile specification (length * width) |

80*40mm |

|

20 |

Machine bed color |

RAL7035 |

|

21 |

Equipment size L * W * H |

1290*980*1700mm |

|

22 |

Equipment weight |

500kg |