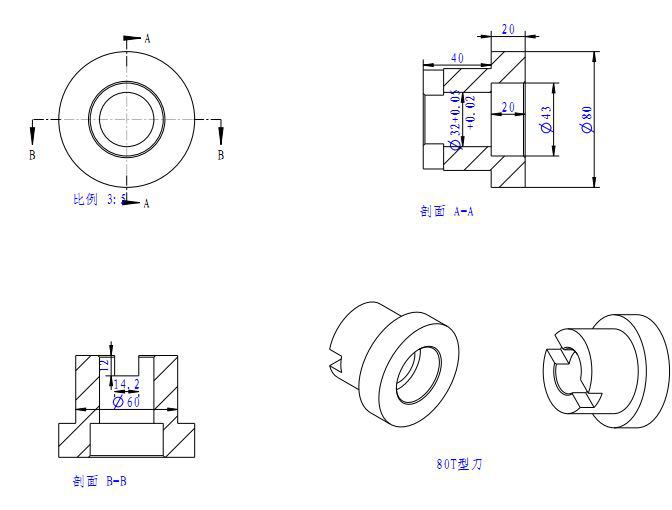

Three sided cylindrical face milling cutter

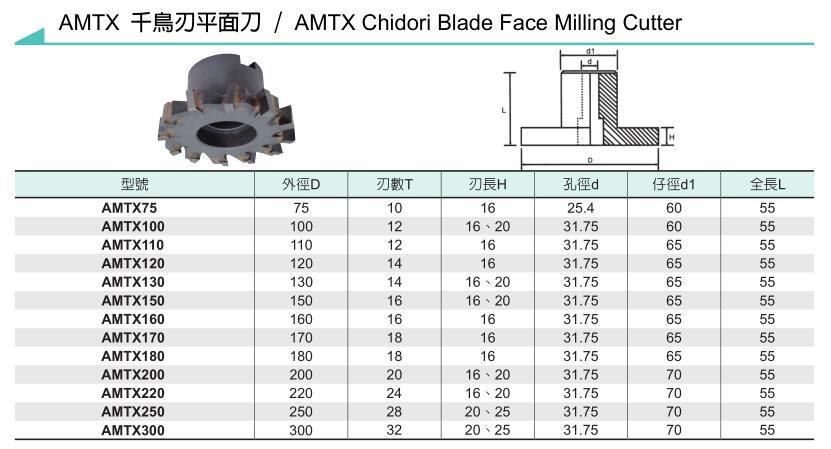

The precision welding edge type cutting tools produced are widely used in various light and heavy cutting processes such as mechanical processing, mold industry, and automotive parts industry. They are made with Taiwan's exquisite technology and advanced tungsten steel blades, welded through various rigorous processes to ensure precision quality. In addition, through continuous research and development, the tool life value is maximized, greatly reducing processing costs for users. For standard commonly used cutter types, such as "fine/rough end milling cutter, T-shaped cutter, three side milling cutter, dovetail slot milling cutter, chamfering cutter, cylindrical fine/rough milling cutter, flat milling cutter head, spare no effort to maintain sufficient inventory, so as to provide you with immediate processing needs, and to provide non-standard customized and various tool maintenance services, including blade change, cutting and grinding the bottom edge, blade sharpening, diameter change and handle change, etc., please feel free to contact your service needs!

The material of the company's welding alloy milling cutter blade shall be welded with Taiwan Chunbao hard alloy, and the processed steel parts shall be processed with hard alloy grade P10 (relative to domestic grade YT15 YT14). The processed castings shall be processed with hard alloy grade K20 (relative to domestic grade YG6). The stainless steel shall be processed with hard alloy grade M10 (relative to domestic grade YW1 YW2). The cutter body material shall be processed with high-quality Tool steel!

Non standard customized cutting tools are made by applying high-quality hard alloys from various brands in Europe, America, and Japan according to different processing requirements of customers!