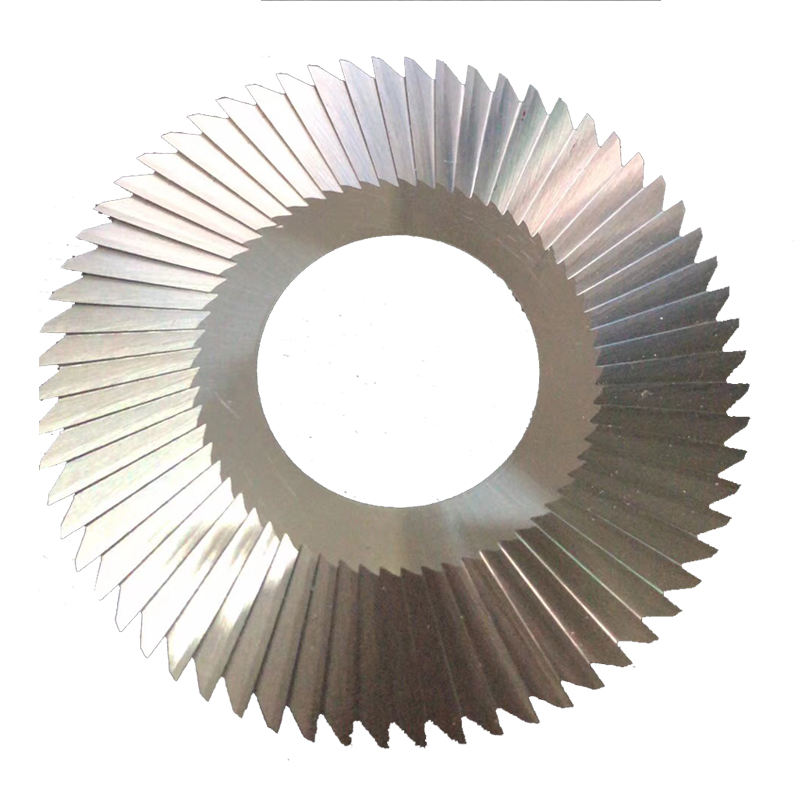

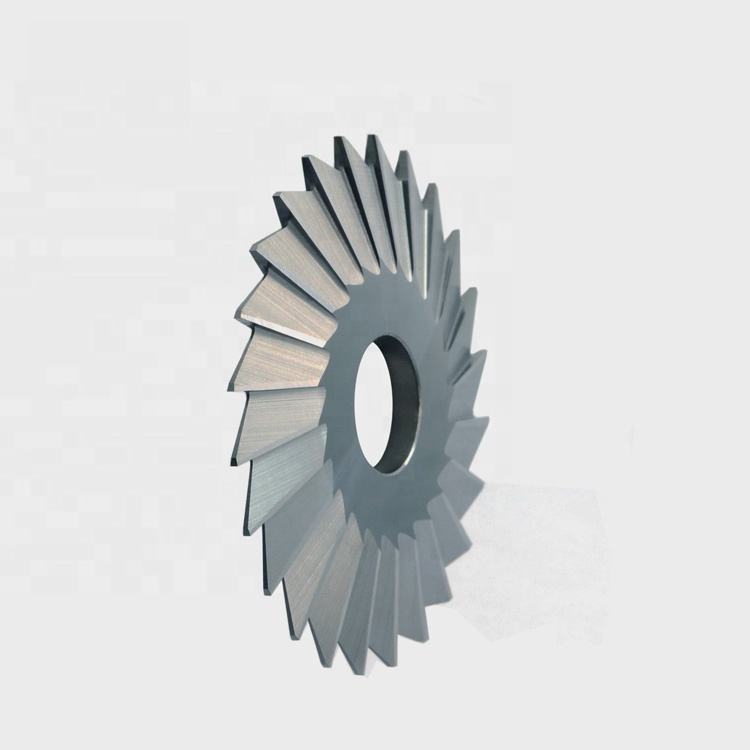

Carbide overall forming saw blade milling cutter

Application scope

Hard alloy saw blade milling cutter: The entire saw blade milling cutter is produced from hard alloy material (also known as tungsten steel), mainly used for processing metal or non-metallic materials such as alloy steel, stainless steel, high-strength steel, quenched and tempered steel, titanium alloy, non-ferrous metal, etc. Its main feature is longer service life compared to high-speed steel saw blades, and the product is widely used in industries such as machinery, light industry, and hardware. The cutting edge of the cutting tool is flat, with good smoothness and high wear resistance work efficiency. After use, the saw blade milling cutter can be re sharpened and reused to extend its service life.

Processing materials

Alloy steel, stainless steel, high-strength steel, quenched and tempered steel, titanium alloy, non-ferrous metals;

High carbon steel, cast iron, aluminum, copper, plastic, wood, rubber, fabric, etc.

purpose

Sawing, cutting, and cutting of various metal or non-metallic materials;

Milling, grooving, and slotting of various metal materials or non-metallic workpieces;

It can also be used for the processing of fabrics such as plastic, rubber, PVC, paper, and cloth.

Production specifications

(Unit: MM):

Saw blade outer diameter: 8-350MM

Saw blade thickness: 0.10-10MM

Saw blade inner hole: above 2MM

You can customize the specifications and shapes you want according to your production and processing requirements